FPS Maintenance

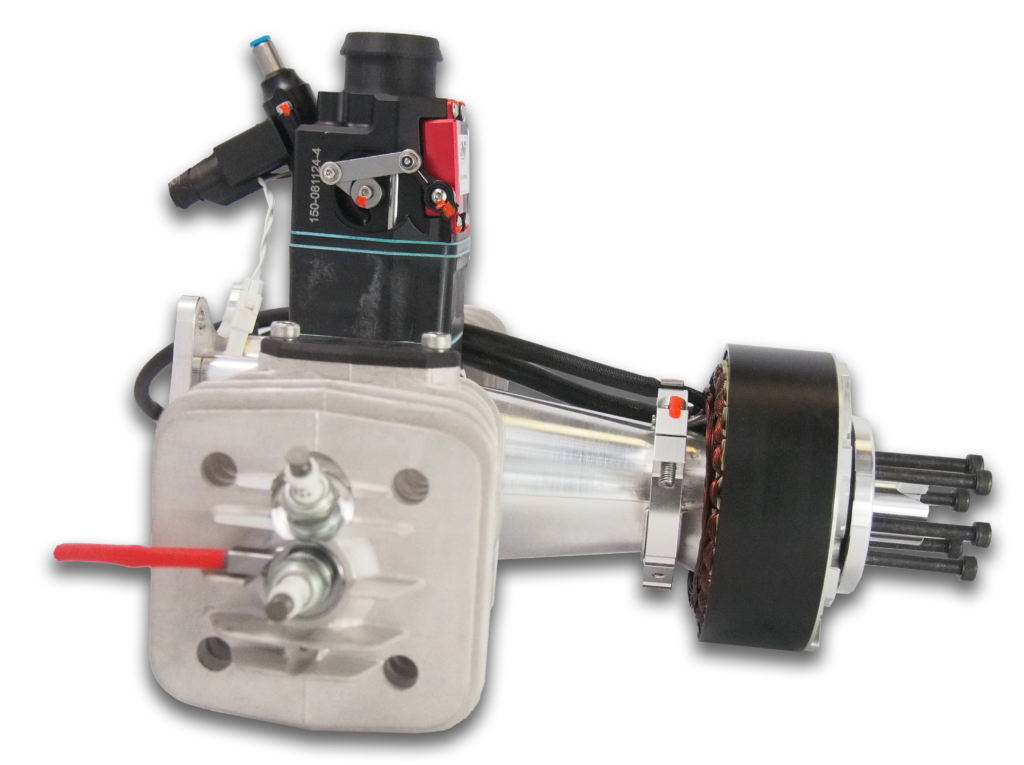

The aircraft uses one of two high-performance, two-stroke DA150 engine mounted at the rear of the fuselage in a pusher configuration. The engine assembly includes the RPM sensor, carburetor or fuel injector made by INF, throttle servo, ignition module, vibration mount, and propeller. Fuel is held in an integral composite tank located within the fuselage. The tank is equipped with anti-slosh baffles and an internal fuel filter.

The engine should be inspected before each flight during the Preflight Inspection. Additional maintenance procedures are performed according to the Carbureted Maintenance Schedule or the EFI maintenance schedule or as needed.

Carbureted DA150

Fuel Injected DA150

Contents

Engine Hardware

| Item | Fastener | QTY | Torque | Threadlocker |

|---|---|---|---|---|

| Spark Plug | NGK CM-6 | 2 | 90 in/lbs | n/a |

| Propeller (wood) | M5 x 55 SHCS | 6 | 65 in/lbs | n/a |

| Propeller (carbon) | M5 x 80 SHCS | 6 | 80 in/lbs | n/a |

| Muffler Bolts* | M5 x 20 SHCS | 4 | 70 in/lbs | n/a |

| Cylinder Base Bolts | M5 x 16 | 8 | 70 in/lbs | Blue Loctite 243 |

| Crank Case Bolts | M5 x 25 | 4 | 90 in/lbs | Blue Loctite 243 |

| Carburetor Mount Bolts | M5 x 75 SHCS | 2 | 50 in/lbs | n/a |

| Engine Standoff Mount | M6 x 25 SHCS | 4 | 65 in/lbs | Blue Loctite 242 |

| Engine Vibration Mount | M6 Stud #9225K65 | 4 | n/a | n/a |

| Engine Vibration Nut | M6 Nylock | 4 | n/a | n/a |

*Use Permatex 81630 Ultra Red High Temperature Gasket Maker between cylinder and muffler.

Spark Plug Replacement

Tools needed: socket wrench, flathead screwdriver, 9/16" or 14 mm spark plug socket, 90 in/lbs torque wrench.

- Ensure the aircraft is powered off, all batteries are disconnected, and the engine is cool.

- Disconnect the spark plug boot from the spark plug.

- Remove the spark plug.

- Inspect the spark plug and insulator for damage and wear. The insulator should not be cracked. A normal spark plug will have brown or grayish-tan deposits on the side electrode. Burned plugs, or those with carbon fouling or oily residue, indicate a problem with the fuel/air mixture or fuel/oil mixture. Worn electrodes will appear eroded. Use the original spark plug if the condition is good or replace it with a new one.

- Ensure the spark plug gap is between 0.018 to 0.020 inch (0.38 to 0.5mm).

- Install the spark plug.

- Torque the spark plug to 90 in/lbs.

- Reconnect the spark plug boot.

Propeller Replacement

The aircraft uses a 32 x 18 wood 2-blade propeller.

Tools needed: 5 mm hex driver, 65-80 in/lbs torque wrench depending on propeller material.

Removal

- Ensure the aircraft is powered off, all batteries are disconnected and the engine is cool.

- Note the propeller orientation and direction before removal.

- Remove the propeller bolts and propeller plate.

- Remove and discard the old propeller.

- Inspect the engine shaft hub thread and propeller bolts for damage. Replace any bolts that are bent.

Installation

- Insert the new propeller onto the propeller hub. Ensure the propeller is not mounted backwards.*

- Align the propeller and compression stroke in a way that is ideal for hand propping.

- Reinstall the plate and prop bolts. Gradually hand-tighten each bolt using a star pattern before torquing to 90 in/lbs. Do not apply thread locker.

*If using EFI engine, ensure that the stator holes are aligned with the alternator holes before inserting bolts.